Digital Manufacturing - Overview

SAP Digital Manufacturing Cloud (DMC) is a solution offered by SAP designed to help manufacturers optimize and digitize their production processes. It provides various tools and capabilities to assist manufacturers in improving efficiency, reducing costs, and enhancing production quality.

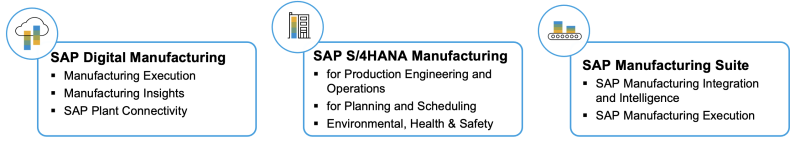

SAP Digital Manufacturing Solutions is a complete portfolio of manufacturing solutions to support digitalization and Industry 4.0

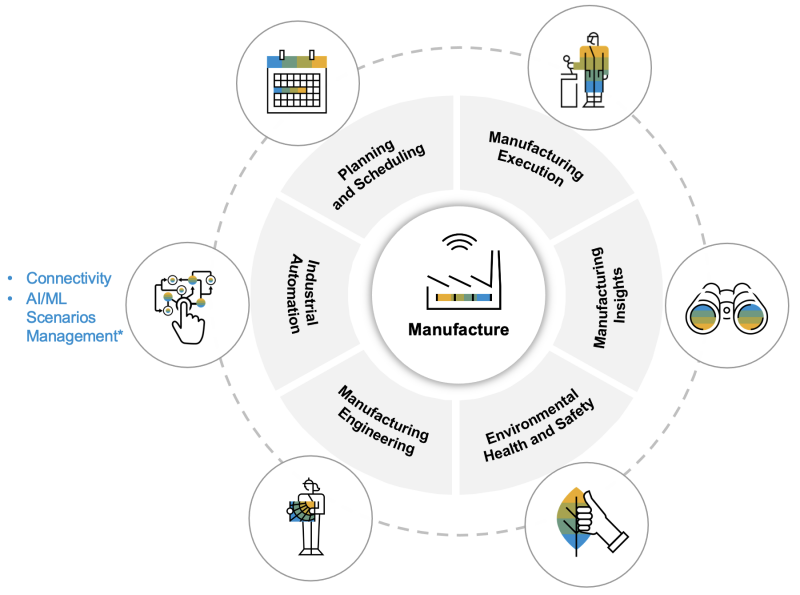

Connect your upper-level business systems with your shop floor equipment for global visibility across all manufacturing facilities while efficiently managing production operations down to each work center. Utilize the power of the manufacturing network to enhance flexibility and explore new business models.

Capabilities DMC

- Manufacturing Execution: Leverage cutting-edge technology hosted on the SAP Cloud Platform to oversee and govern shop floor activities seamlessly. Benefit from seamless integration with SAP ERP and S/4HANA for streamlined orchestration and control.

- Manufacturing Insights: Harness the potential of the Data Lake and Common Data Lake to gain valuable insights into both discrete and process industries. Asset Central is a common data foundation for master and transactional data, such as equipment and work orders.

- Real-time Decision Making: Make informed decisions in real-time to boost productivity and optimize the performance of your production systems. Conduct root cause analysis and employ predictive models based on machine learning to identify product quality defects early in the production process.

- Collaborative Networking: Collaborate with partners within the network to develop digital inventories that enhance the optimization of your offerings. Serve as a digital twin of the physical world, encompassing all equipment and automation devices.

- Bridging IT and OT: Enable seamless data exchange between Information Technology and Operational Technology within a manufacturing environment, facilitating streamlined processes.

With SAP Digital Manufacturing Cloud, you can revolutionize your manufacturing operations, ensuring efficiency, quality, and adaptability in the ever-evolving business landscape.

Features DMC

The key features and capabilities of SAP Digital Manufacturing Cloud include:

- Real-time Visibility: The solution offers real-time visibility into production processes, allowing manufacturers to make better decisions and respond quickly to changes in demand or production conditions.

- Production Planning and Execution: SAP Digital Manufacturing Cloud supports manufacturers in planning and managing production orders, tracking progress, and optimizing production scheduling.

- Quality Management: It provides quality control and assurance tools to ensure product quality and minimize defects.

- Maintenance Management: Manufacturers can optimize maintenance activities by planning preventive maintenance and conducting fault analysis.

- Connectivity and Integration: The solution can be integrated with other systems and IoT devices to collect and share data from various sources within the production environment.

- Digital Twin: It utilizes digital twin technology to create a virtual representation of the physical production environment, allowing manufacturers to simulate and optimize processes before implementing them in actual production.

Optimize your shop floor

Automate processes and resources to improve manufacturing efficiency, quality, and productivity

- Paperless production with intuitive user interfaces for production operators, automatic data collections, and set machine parameters, lowering cost and increasing productivity and quality.

- Design, distribute, and dynamically control manufacturing shop floor activities, enabling an intelligent factory

- Shift and Labor planning to ensure business operations with the right qualifications. Production Order scheduling and dispatching consider labor, resource, and maintenance constraints to plan operations and adapt to changes.

- Cross-plant real-time analytics for manufacturing performance, e.g., perfect order fulfillment, Overall Equipment Effectiveness, loss analysis, and machine data to identify improvement opportunities.

Manufacturing Insights: Intelligent insights and analysis across global plant operations

- Adaption to any manufacturing process and global visibility and analytics for key performance indicators across a single plant or global operations

- Full integration to combined business and operational data from ECC, SAP S/4HANA, and the Manufacturing Suite for improved decisions

- Manage and view harmonized data acquired from disparate sources for better visibility into your plant operations

- Business logic orchestration to enable customer-specific processes for planning, execution, maintenance, and quality

- Manufacturing Performance Management withOverall Equipment Effectiveness (OEE) and Energy Management to lower operational costs through an intuitive, tailored Worker UI

Manufacturing Execution: Orchestrate and control the shop floor

- Implement top-floor to shop-floor scenarios to achieve rapid return on investment through out-of-the-box integration to SAP solutions

- Utilize intuitive user interfaces (UI) for production operators and transform to paperless production

- Dispatch and sequence operations to reflect the real world in the short term

- Monitor the entire manufacturing process to optimize resources and execution

- React quickly to unexpected events

Automate processes and resources to improve manufacturing efficiency, quality, and productivity

- Enable resource orchestration by dispatching and sequencing operations to compress the manufacturing lifecycle and provide real-time production performance tracking

- Implement top-floor to shop-floor scenarios to achieve rapid return on investment through out-of-the-box integration to SAP solutions

- Utilize intuitive user interfaces (UI) for production operators and transform them into paperless production, lowering cost and increasing productivity.

- React quickly to unexpected events by monitoring the entire manufacturing process to optimize resources and speed execution utilizing built-in intelligence

- Collaborative integration to allow you to respond quickly to unexpected events

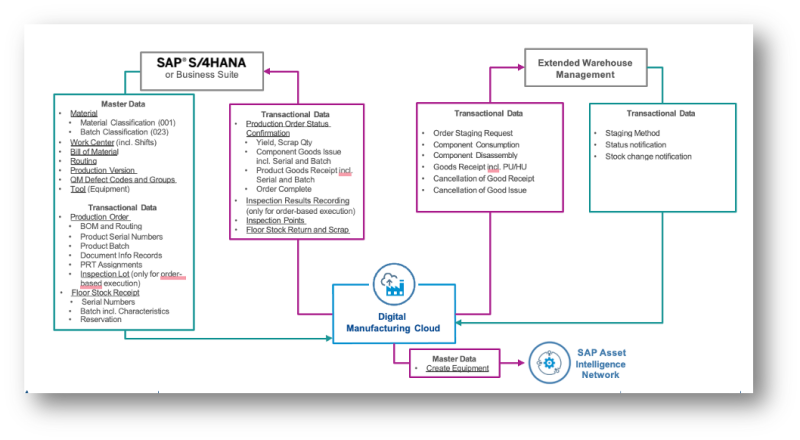

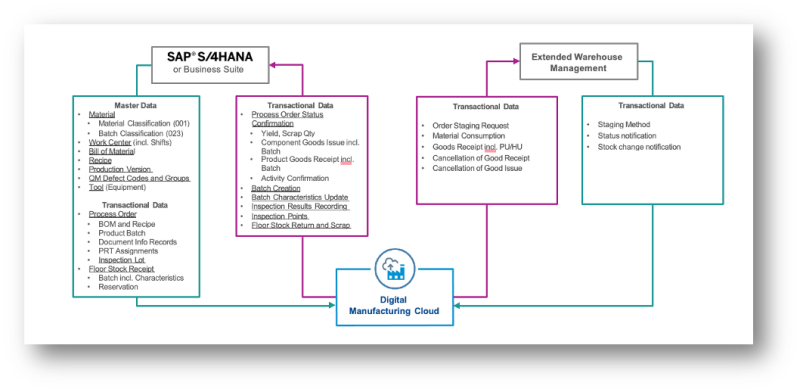

Integration

Discrete Manufacturing

Discrete Industries Integration Scenarios for DMC – S/4HANA or Business Suite

Process Industries

Process Industries Integration Scenarios for DMC – S/4HANA or Business Suite

Extensibility

UI Extensions (Custom POD Plugin, Custom Application)

- Provides a mechanism to allow customers/partners to develop custom SAP UI5-based POD plugins using SAP Web-IDE

- Step by step guide is available in the SAP Help Portal

- Custom POD plugins becomes available inside POD Designer, thereby allowing them to be consumed inside POD

- Alternatively, the customer/partner might use the public APIs available in the SAP Business API Hub to create a full SAPUI5 Custom Application in the customer/partner PaaS tenant.

- Template Assembly POD is provided by SAP, including step by step guide on SAP Help Portal

Machine Learning Extensions

- Bring your own model for Visual Inspection Scenarios

- Download image and inspection results collected through usage of POD Plugin Visual Inspector

- Train your own classification or defect detection model using preferred machine learning tools and convert it to TensorFlow Javascript model files

- Upload your own model files using the wizard for the creation of new visual inspection scenarios

- Activate visual inspection scenarios with their own model to be used by the POD Plugin Visual Inspector

AI/ML Scenario Management

AI/ML Scenario: Visual Inspection - Assist Nonconformance Logging

Machine learning models assist operators on the shop floor in executing visual inspection tasks of manufactured products. Using a Production Operator Dashboard simplifies the identification of defects and logging the right Nonconformance to ensure defective parts are handled as business requires.

- Upload a pre-trained machine learning model and deploy it to the shop floor, supporting the operator on visual inspection tasks.

- The operator can capture images with connected cameras or can inspect images from industrial cameras provided by the data collection API

- Assist operator in identifying defects and logging the right Nonconformance code using the machine-learning model

- Allow the machine learning model to log the Nonconformance automatically based on the prediction and under the operator’s control

- Automated collection of images and inspection results, which can be reviewed, analyzed, and downloaded as analytical data sets to train new machine learning models.

GxP Management

GxP Management in the context of digital manufacturing refers to the adherence to Good Practice (GxP) guidelines within the manufacturing process, particularly in industries like pharmaceuticals, biotechnology, and food production. This involves ensuring that various aspects of production, including equipment, procedures, and documentation, comply with industry standards and regulatory requirements. GxP Management in digital manufacturing leverages technology to maintain quality control, ensure product safety and efficacy, and traceability and accountability in all stages of the manufacturing process.

Regulatory Compliance

Operational Scope - Development Operations and Quality Assurance:

How do SAP Business Technology Platform and SAP Digital Manufacturing develop new features, document and test them, and how do they ensure quality?

- Implement an over-arching content and quality management system (processes, documents, training of our teams)

- Regular enforcement of process compliance.

- Be ready for customer audits for data integrity and compliance.

- Conducting GxP audits (Self Inspections)

- Implement required control and practices to harmonize the documentation, training, software development, software testing, etc.

Technical Scope - Products Qualification

How is SAP Business Technology Platform as a platform and Digital Manufacturing as a product on it operated in the Cloud?

- SAP Digital Manufacturing Product Qualification

- SAP BTP Platform Qualification

- SAP BTP supplied Services Qualification

- SAP DM Supplier Qualification

- Release process harmonization

- Maintenance practice enforcement of the Qualification status of the product.

Functional Scope - Functional Requirements in Digital Manufacturing

What is needed in Digital Manufacturing as a Manufacturing Execution System in order to enable a GMP-compliant manufacturing process?

- Define functional requirements for Digital Manufacturing and SAP Business Technology Platform services

- Handover of requirements to SAP Business Technology Platform units for t-shirt sizing and to get commitment

- Master Data Change & Approval Management

- Electronic Records + Printing

- Audit Trail

- Worker Guidance

- Digital Signature

- Electronic Batch Record + Deviation Analysis